Most of the basics common to bedding plant production are the same for medical cannabis plants. Sunshine or supplemental light, humidity control, air movement, sanitation, nutrition, tightly monitored irrigation, and sound horticultural practices all lead to quality.

Gary Mangum has spent most of his career working in then one of the largest greenhouse and nursery operations in the U.S. He now operates ForwardGro as the first licensed medical cannabis grower in the state of Maryland. Gary didn’t retire from one to move to another, but circumstances created the opportunity to learn yet more about this new industry.

Gary Mangum has spent most of his career working in then one of the largest greenhouse and nursery operations in the U.S. He now operates ForwardGro as the first licensed medical cannabis grower in the state of Maryland. Gary didn’t retire from one to move to another, but circumstances created the opportunity to learn yet more about this new industry.

Greenhouse Grower caught up with Mangum recently to ask about what he has learned since ForwardGro opened its doors in early 2017 and about some of the similarities and differences he sees between growing ornamentals crops and growing cannabis.

Greenhouse Grower (GG): Now that it’s been a few years since ForwardGro opened for business, what have you learned along the way?

Gary Mangum (GM): Just as with any new business, ForwardGro is a startup, and we’ve had to learn lessons along the way. We’ve had some setbacks but, overall, we’ve managed to emerge strong and determined to grow the best medicine possible. We’ve been able to go back to our roots and focus much of our collective energy on consistently growing and producing the very best flower/medicine possible. The cannabis plant grown for replicable medical purposes is one of the most unique plants I’ve ever experienced. Our respect for its complexity is real, and the need to handle each aspect of pre- and postharvest with ongoing attention to detail and care is real.

GG: What are your greatest challenges in this business, and your greatest wins?

GM: We were the first to complete our growing facility in Maryland, and therefore, we were inspected and licensed first. There was no advantage to being first, but some would consider that a win.

Because we’re producing medicine, there are necessary compliance and security protocols that are very important. We continue to appreciate and acknowledge the importance of the Maryland Medical Cannabis Commission (MMCC). The focus on patient safety is very important to the success of the program. We have always had a healthy respect for the mission of the regulators and the needs of the patients.

Medicinal-quality cannabis is difficult to grow. It takes patience and a knowledgeable team to effectively produce to reliable scale. I always find it worthwhile to spend time in the greenhouse, where I’m most comfortable making suggestions. Our team has all the answers, and is typically well ahead of anything I may add. We encourage and listen to their ideas, and they proudly share new improvements or R&D outcomes. Our cultivation manager is exceptional. She is one of the strongest and most focused cultivators in the state. Her biology background and open-minded approach to collaboration and growing in the greenhouse environment has helped us consistently create medicine that patients want. We will continue to produce with sustainable methodology that allows us to offer a strong value.

GG: What are the differences between growing medical cannabis versus growing bedding plants?

GM: Our facilities are more pharmaceutical-like, more in line with how the traditional Ag breeders manage their Research and Development facilities. Our team suits up in protective clean gear for all plant-touching work pre- and postharvest.

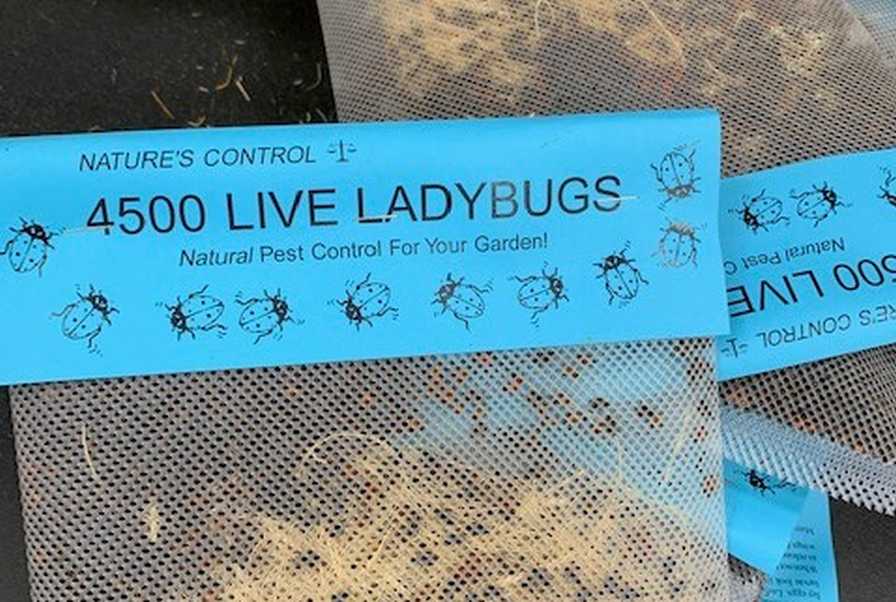

The plants can be susceptible to a variety of pests and disease — virtually the same range as bedding plants. We have an aggressive Integrated Pest Management program in place to keep the plants clean and healthy, and it works. The same biological controls used for bedding plants are also used by some of the most horticulturally advanced cannabis grows. Ladybugs are equally popular in both worlds, and plant physiology is plant physiology, though I’d say cannabis offers more unique challenges.

Maryland has been very deliberate and slow related to approvals for crop-protection agents. My guess is that if this industry were allowed to use the federally regulated term organic in our production, many would qualify to do so. A wide range of testing by independent labs is mandated prior to sale of product to dispensaries or processors in Maryland. The system in place recently allowed the MMCC to place a full product hold on vape products as a particular search was initiated. A week later, the hold was fully lifted as the testing regime showed the potential concern was not in the Maryland regulated medical market. Kudos to the MMCC for being positioned to take action and provide conclusive data. Science versus innuendo or emotion is excellent to utilize.

Most of the basics common to bedding plant production are the same for medical cannabis plants. Sunshine or supplemental light, humidity control, air movement, sanitation, nutrition, tightly monitored irrigation, and sound horticultural practices all lead to quality. Even though many refer to cannabis as “weed,” I would say that’s a real misnomer in an indoor environment. Successfully growing cannabis on this scale to consistently satisfy medical needs is a complex task.

With bedding plants, pre-harvest is where virtually all the action takes place. With cannabis plants, both pre- and postharvest activities are vitally important to the finished products quality, and the value of the finished products, generally determined by the cannabinoids and terpenes, which influence the patient experience.

GG: How do the two businesses differ? What’s similar?

GM: The similarity is that we’re in a greenhouse and, having worked in greenhouses and around professional growers for a good portion of my life, we understand the importance of creating and managing the best environment possible.

One example of a difference we learned the hard way early on is that cannabis is more sensitive to light than even the most photosensitive plants I’ve experienced. With cannabis, light leaks can create stress and cause a genetically female plant to express male traits. This can lead to self-pollination, causing unwanted seed production, which is undesirable in the medical market. For that reason, it’s important to eliminate all stressors possible. Photoperiod interruptions, temperature extremes, and genetics can all impact normal growth. Bedding plants are able to stand up to more variable conditions, occasionally leading to bud delay with particularly hot weather, but that’s not a scenario that typically ruins or dramatically reduces the value of a crop.

Another major difference is the regulatory environment that overlays medical cannabis production. In this business in Maryland, there’s either a law or a rule or continuing inspection that the state has in place informing most every move we make — we actually feel good about that. With the rigorous testing standards that the MMCC has developed, patients can be confident. If the regulatory environment isn’t enough to create exposure to risk, then the fact that much of what this industry does is still considered federally illegal no doubt keeps some awake at night as the federal government works to catch up with state laws and activity.

Lastly, but perhaps the most important difference is that cannabis is grown for patients and human consumption and that must be top of mind at all times and in every action.

GG: How do the two industries compare in profitability? Demand?

GM: There are some cost similarities to the startup infrastructure, though if you are building for cannabis, plan on payment in advance in many situations. The fact that we had experience building or acquiring many acres of greenhouses in the bedding plant world definitely helped us move ahead with a sustainable design and prompt buildout. Working closely with our long-term sales contact, Jeff Warschauer of Nexus, helped ensure that we got the best value possible.

Demand for our medicine is solid. We’re working to carefully increase our production to help grow our footprint and participate in filling the growing demand for medical use in Maryland. Bedding plants, perennials, or tropicals are typically selected based on appearance or how they show and occasionally how they grow. Medical cannabis is chosen for its effect on the patient, with less regard for appearance and how it grows.

Based on our facility investment to date, overhead costs, and tax treatment related to the business, we expect to move to a profitable position soon enough. While we have moved recently to positive cash flow, we’re still lacking any return on investment.

We’ve chosen to build our business as a value provider because we built with sustainable practices top of mind. Pricing is elastic to some degree, but we believe the importance of consistent production and maintaining a value-based focus will position us well for long term success.

GG: What are some of the successes since you started several years ago? How do you measure success?

GM: Success for us is getting our medicine to those who need it most. Hearing from dispensaries that patients are regularly asking for our product is a great feeling. That to me is success, and it means we’re filling an important need. I’m happy to share that we’re the first in Maryland to post all of our Certificates of Analysis Independent Testing results at ForwardGro.com as we receive the results weekly. Patient advocates have expressed their appreciation for this effort.

It’s taken us longer than initially expected to get to the point of phased expansion, as we had to shift from our earliest efforts and execute some tough internal changes. We believe we are now well situated for continued growth. Our team contributes in a positive way every day, and people are happy with their work.

GG: Where do you see ForwardGro in five years? Where do you see the industry overall in five years?

GM: We expect that we’ll be a significant supplier of predictably high-quality cannabis, able to effectively meet the growing patient demands. In five years, we expect that the industry will be larger and much more significant in Maryland. Every day more people are hearing about the benefits of these plants. Everyone in the state should be able to get the medicine they need. Hopefully, within the next five years, the federal government and traditional medical insurers will recognize the long-term value of covering the cost of cannabis for medical use. In addition, our legislature is considering opioid substitution and adult-use. As time progresses, clarity regarding these potential impacts will develop.

GG: What advice would you give someone thinking about getting into this industry?

GM: While financing is important, spend as much time as necessary to build the strongest team possible. Treat your team like you’d want to be treated. Our team is by far our biggest asset. In this highly competitive and regulated business, every move a leader or a team member makes during the course of the workday here contributes to the satisfaction of Maryland’s patients and the success of this highly regulated business. In my former business life, our most often used internal mantra was “Act Like you Own It.” That works for this business as well, but with reasonable constraints in place.

In some parts of the country, there is clearly too much supply. In others, not enough. Make sure you’re in an area that will need your product in coming years, and don’t expect to be able to jump right in. Pay attention to the regulatory and tax environment.

As our business moves to profitability, we will likely invest more resources in more aggressive federal government affairs work. The fact that some of those that we employ in government won’t work to create a federally legal banking structure for this industry is well beyond frustrating. Treating our legal industry as a criminal undertaking for tax purposes is also most unfair. It’s possible our existing elected officials can get the banking dilemma fixed, but equally possible that elections will need to help shift the current thinking around banking and tax code changes for this legal medical treatment.

GG: If you had to do one thing different what would it be?

GM: That’s a tough question as we’ve learned so much over time. More focused energy would have been spent searching for an established, horticulture-based greenhouse grower. Moving any individual from growing outside in a non-regulated environment to a state-of-the-art greenhouse or indoor grow in a heavily regulated industry could prove to be a bridge too far. Initial postharvest activities would also have benefited from an early focus on more experienced key personnel. We’re in a great place now, and our entire team is proud of what’s been created.

GG: What is one thing you would do again?

GM: We/I would spend more time earlier on team development, but would definitely rehire every member of the team that we have in place today, and help make sure they have the tools to get everything done every day in a way that we can all be proud. I’d want to make sure to repeat the positives, and that starts with the team in place.

GG: Is there anything we haven’t covered that you think would be important for the industry to know about ForwardGro?

GM: For me, it’s important to acknowledge how much there is to learn in this industry. Wanting to be the best doesn’t make it happen. Innovation, quality, service, and value are going to be differentiators in this space as they were in my own more traditional experience in the grower segment.

I think it’s very important to understand the critical value of our employees if we are to be an innovator and gain market share. From the grow and postharvest teams, to the group that keeps the facility operating at the highest level, every single person plays an important role. My role really is minimal, but directional. The empowerment of our people and willingness to listen to the ideas our folks share does help ensure a positive future for the business. We are together focused on the patients of Maryland and their satisfaction.

We also know there are real needs to engage and help create a logical system for compassionate care assistance in Maryland, and hope to contribute to that discussion at some point. Fairness in licensing is another thing that has to be looked at hard. In Maryland, racial diversity related to ownership has become a very serious need that is still being sorted out by those that understand the appropriate solutions.

Finally, while virtually everything about government is slower than I would think it could be, I have to say I’m very proud that we are operating in one of the strongest state programs in the country. Our legislative leaders, the various committees, and the full legislature has really created the framework for an excellent program in Maryland. The MMCC has been empowered to regulate and look out for the patient needs of Marylanders. The MMCC Chairman, and the professional staff leadership, have a productive relationship with the legislative leaders and body, patient advocates, as well as those they regulate.

Collaboration with industry can always be beneficial, and that may be an industry-wide desire to become more involved in dialogue at an earlier point for the good of the patient and health of the industry.